Product Description

This 17.2 mm diameter, 3-meter-long earth rod is engineered for high-performance grounding applications. Manufactured with a low-carbon, high-strength steel core and bonded with a minimum of 254 microns of copper, it offers superior conductivity and corrosion resistance, ensuring long-term stability in diverse environmental conditions.

UL listed and rigorously tested, this earth rod is suitable for use in industrial, commercial, and utility installations where reliable grounding is critical. Its uniform copper bonding provides excellent resistance to oxidation, making it ideal for both dry and high-moisture soil environments.

Technical Specifications

| Manufactured as per IS 3043:2018, BS 7430 standard |

| Low Carbon Tensile Steel (Cold Drawn) Rods as per AISI 1018 / SAE 1018 / BS 970 |

| In-house Cu rod plating facility with Non-cyanide (Alkaline) copper plating process (Non-polluting) |

| Coated with 99.9% pure Electrolytic Grade Copper of minimum 254 micron thickness as per BS 4360 grade 43A |

| Meets the requirements of IEC 62561-2 |

| In-house testing facility – Tensile Strength Test, Hardness Test, Bending Test, and Adherence of Coating Test |

| ISO 14001:2015 Certified |

The rods are tested for the following parameters |

|---|

| Ultimate Tensile Strength as per IEC 62561-2:2018 |

| Bend Test as per IEC 62561-2:2018 |

| Salt Mist Cycle Test as per IEC 62561-2:2012 / IEC 60068-2-52:1996 |

| Ammonia Test for Stress Corrosion Resistance as per ISO 6957:1988 |

| Humid Sulphurous Atmosphere Test as per ISO 6957:1988 |

| Adhesion Test as per IS 2629:1985 (RA-2006) |

| Short Time Current & Peak Withstand Test |

Product Description

The 14 mm x 3 meter UL-listed earth rod is engineered to deliver consistent, long-lasting earthing performance for a wide range of electrical and lightning protection systems. With a high-purity copper coating of at least 254 microns, molecularly bonded to a durable steel core, the rod ensures excellent conductivity and corrosion protection.

Designed for critical infrastructure and demanding installations, this rod reduces ground resistance significantly and meets strict international standards. Its robust build and superior finish make it suitable for industrial, commercial, and utility applications where safe and efficient grounding is essential.

Technical Specifications

| Material | Low carbon steel core with pure copper bonded coating. |

|---|

| Length | 3 meters. |

|---|

| Diameter | 14mm |

|---|

| Conductive Compound | Optional (recommended for extremely high-resistance soils) |

|---|

| Typical Earth Resistance | < 1 ohm (based on soil and installation method) |

|---|

| Service Life | 30+ years (in standard soil conditions) |

|---|

| Compliance | UL 467 Listed, IEEE 80, IEC 62561-2 |

|---|

Product Description

VRH GC+ Ground Enhancement Material is a specially engineered compound designed to improve the effectiveness and longevity of earthing systems. It reduces soil resistivity and enhances conductivity, ensuring safe dissipation of fault currents and lightning surges. Its high moisture-retention capability and anti-corrosive properties make it ideal for difficult soil conditions, including dry, sandy, or rocky terrain.

Packaged in 25 Kg bags, VRH GC+ is easy to transport and apply during earthing installation. The compound does not require periodic recharging or maintenance and bonds naturally with surrounding soil, creating a stable and low-resistance interface between the earth electrode and ground for years to come.

Technical Specifications

| Material Type | Conductive carbon-based compound |

|---|

| Packaging | 25 Kg moisture-resistant bag |

|---|

| Color | Black/Grey (powder or granular form) |

|---|

| Resistivity | < 0.12 ohm-meter (when mixed with water) |

|---|

| pH Value | Neutral (6.5 – 7.5) |

|---|

| Application | Surrounding earth rods, pipes, and chemical electrodes |

|---|

| Compatibility | Suitable for all soil types |

|---|

| Service Life | More than 20 years (under standard conditions) |

|---|

| Environmental Impact | Non-toxic, non-corrosive, and eco-friendly |

|---|

| Compliance | IEEE 80, IEC 62561-7, IS 3043 |

|---|

Product Description

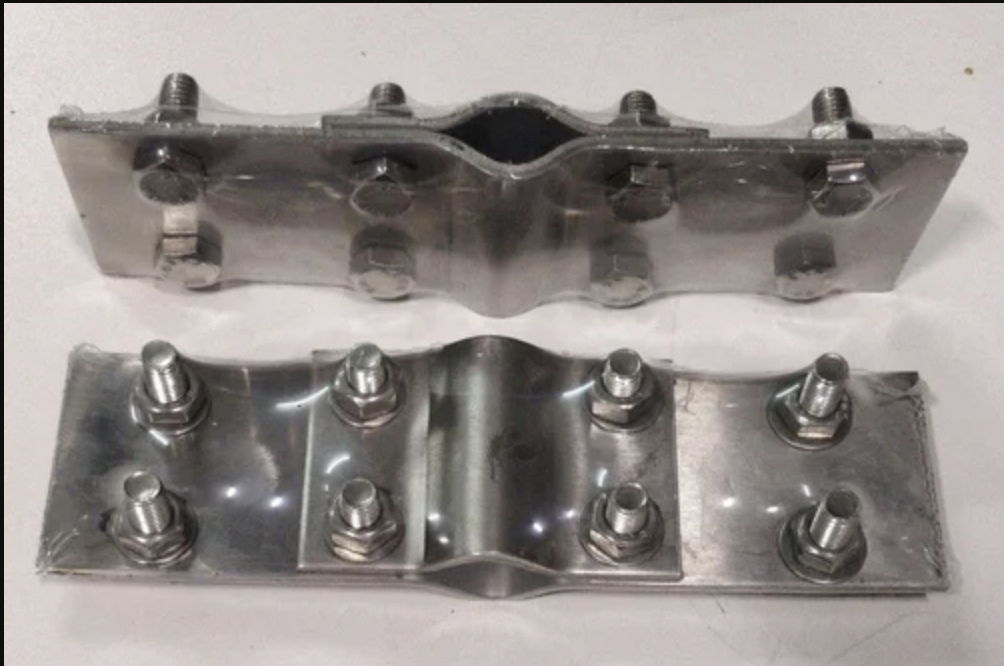

The Stainless Steel Clamp (150X40X3)MM with Nut, Bolt & Washers is a robust and corrosion-resistant component used for efficient grounding terminations. Manufactured using high-quality stainless steel, this clamp is built to withstand harsh environmental conditions while providing a strong mechanical and electrical connection.

With a precise 150 mm x 40 mm x 3 mm profile, the clamp is ideal for securely connecting flat conductors or earthing strips to electrodes or other grounding infrastructure. It is widely used in substations, telecom towers, industrial units, and commercial installations where durability, safety, and conductivity are critical.

Technical Specifications

| Product Name | Stainless Steel Clamp with Nut, Bolt & Washers |

|---|

| Dimensions | 150 mm x 40 mm x 3 mm |

|---|

| Material | Stainless Steel (Grade SS304 or SS316) |

|---|

| Components | Clamp, Nut, Bolt, and Washers |

|---|

| Usage | Termination of earth strips, rods, and conductors |

|---|

| Corrosion Resistance | High – suitable for outdoor and industrial environments |

|---|

| Installation | Manual tightening using spanners/wrenches |

|---|

Product Description

The Heavy Duty Poly Plastic Pit Cover is engineered to protect earth pits while clearly identifying them using pre-molded or printed nomenclature. Made from robust, weather-resistant polymer material, this cover offers long-lasting durability in all climatic conditions. Its non-corrosive nature and excellent mechanical strength make it suitable for industrial, commercial, and utility-scale grounding systems.

This cover is designed for easy installation and secure fitting over earth inspection chambers. It prevents unauthorized access, water ingress, and physical damage to the earthing system while keeping the site organized and compliant with electrical safety norms. Ideal for electrical substations, telecom towers, and sensitive installations.

Technical Specifications

| Product Name | Heavy Duty Poly Plastic Pit Cover |

|---|

| Material | UV-stabilized polymer/plastic (non-conductive) |

|---|

| Dimensions | Standard fit for 250 mm / 300 mm diameter earth pits |

|---|

| Color | Black or Green (custom options available) |

|---|

| Markings | Pre-molded or engraved Earth Pit identification text |

|---|

| Load Bearing Capacity | Up to 5 tons (varies by model) |

|---|

| Application | Cover and identification of earth pits in grounding systems |

|---|

Product Description

Exothermic welding using graphite moulds and exothermic powder is a proven method for creating strong, corrosion-resistant, and highly conductive electrical connections. The process produces a high-temperature chemical reaction that permanently bonds conductors such as copper rods, cables, and strips at the molecular level — ensuring a low-resistance, long-lasting connection.

The system includes a graphite mould customized for specific connection types and exothermic welding powder (in measured grams) that initiates the thermite reaction. Exothermic welding is widely used in power distribution, lightning protection, and critical grounding systems where reliability, conductivity, and lifespan are crucial.

Technical Specifications

| Product Name | Exothermic Mould and Exothermic Powder |

|---|

| Mould Material | High-quality, heat-resistant graphite |

|---|

| Powder Composition | Thermite-based copper alloy powder |

|---|

| Available Powder Sizes | 45g, 65g, 90g, 115g, 150g (based on joint type) |

|---|

| Applications | Earthing, grounding, lightning protection, telecom towers |

|---|

| Ignition Method | Manual flint igniter or electronic ignitor |

|---|

| Joint Quality | Permanent, corrosion-free, high conductivity |

|---|